Good morning everyone and welcome back to TFB’s Silencer Saturday brought to you by Yankee Hill Machine, manufacturers of the new reduced blowback YHM Turbo T3 rifle suppressor. Last week we discussed the universal 1.375 x 24 mounting system and it’s applications throughout the industry. This week we get to have a conversation with Karl Brügger, owner and chief visionary of B&T – formerly named Brügger and Thomet. A few months ago, my suppressor brother-from-another-mother, Austin R. traveled to Switzerland with TFBTV’s James Reeves to spend a few days with Karl and the B&T team.

My sincere thanks to Karl and the rest of the big brains at B&T for allowing us to peek behind the curtain, sharing their vast knowledge, and for being gracious and accommodating hosts. I’d also like to thank Austin for all of his hard work to bring this interview to our readers.

B&T @ TFB:

- The Rolex of Tactical Pistols: The B&T USW-P 9mm

- NEW B&T KH9 Covert: A Packable 9mm Carbine

- SILENCER SATURDAY #243: Full Auto Rimfire – B&T 22 Suppressor Review

- Pocket-size Cyberpunk SMG: The B&T TP380

- B&T USA Delivers Exclusive GHM9 SD Model to The Armories

- SILENCER SATURDAY #237: Back Pressure Beast – B&T USA 7.62 RBS Compact SF

The Interview: Talking Suppressors with Karl Brügger from B&T

Although he will never admit it, Karl Brügger, the sole owner of B&T, is a maverick in the suppressor industry. During our recent trip to Switzerland I had to a chance to tour B&T’s Swiss Headquarters and interview the man behind all the magic from B&T. Here’s what I learned.

TFB (Austin R.): When did you start making suppressors?

Karl Brügger: In 1985, I was in my apprenticeship as a mechanic, and I was in the Federal Powder Plant. I was a young student learning mechanics. And there we had a project for the Swiss Army where we made kind of a suppressor for the Secret P 26 Army or whatever this organization was called. And I was involved in making some of those suppressors.

Karl’s Legacy Suppressors

So that kept my interest in suppressors from the age of 18-19. At the same time, I started practical shooting, and I bought a Mini UZI. And at that time, there was no need for a license to produce or make your own weapon or suppressor as long as you did not make any money out of it. So for your own use, you could make a suppressor. So I asked my teacher at the powder plant, can I make a suppressor? And the rule was clear. He said, yeah, you make the drawing of how it should look, and I put in the tolerance on the parts that you make. The parts have to be as exact as possible so that you learn something from it.

Early B&T Suppressor Markings

So this Mini UZI suppressor is by far the most accurate I have ever done in my career. So that’s how it started. And I had that we took to the range and we shot it. People saw it at that time. Some guys who were young colleagues of mine in the police, they saw that, and they said, that’s interesting. Can we get some too? And that’s how we started making suppressors for friends at a young age. So when I finished my education, I went to the army and I made some for some gun shops where Thomas, my former partner, was involved. I made them suppressors so that they could use their guns. So that was like a hobby in one way.

Legacy Suppressor Endcaps and Mounts

And then in 1991, we decided to found B&T Brugger and Thomet. And we started to make suppressors in the backyard of a small shop with, I think, 150 square meters. With just a lathe a mill, a welding machine, and we start to import pistols, and yeah, we never had a plan. We just started and tried our best.

TFB: So B&T starts as a suppressor company and then firearms as well, or sort of both at the same time?

Karl’s Integrally Suppressed Makarov

Karl Brügger: At that time we were a gun dealer making suppressors for the Swiss civilian market. That’s how it was. At that time HK was not really represented. We came in contact with HK in 1993 and we get HK representation for the Swiss market. So we started to import HK weapons and during that time we got contacted by HK that we also eventually could make some suppressors for them. So that’s how it slowly, slowly started. And HK then started to be a really good customer of ours in 1994, 1995. So HK was our first OEM and we’re still a supplier of them, we still love them, and we love their product.

TFB: Was one of these suppressors for the H&K roller locks produced during that time?

Karl’s Personal HK P7M13 and P7K3

Karl Brügger: The suppressor was mainly for the MP5, and they started with the USP tactical at that time. And then they came to us with a Mark 23 request. They basically gave us the design of the recoil booster how it is today. I think they also gave that to Knights Armament, but they wanted to have a European supply for their cans, as the Americans had a hard time exporting that. So we made our own version of a Mark 23 can for HK with their recoil booster design, which we used also till today. But we had our baffle stack in front and our way of doing it.

TFB: And since their original development, I’ve heard your pistol cans have remained very similar to the original design. Is that true?

B&T Pistol Suppressors

Karl Brügger: Yeah. The science or design from 1998 is identical to what we have today. There is just the adoption between the weight of the moving mass, the spring tension, and the piston. They vary a bit, but the general system is still identical to 1998. And the star baffle design, I mean, to be very frank, it’s a combination of something we did at the Federal Powder Plant, a design of kind of star-shaped baffle. We simply added the step like it was used in the stand to get, like, streams inside. That’s the only thing we did. But star baffles, I don’t say it’s my design. We optimized that design for the Ten CNC machines we had. And that’s how it came out. And it’s still today, it’s made out of solid on the machine. Runs a couple of minutes on the machine and we still haven’t found a better baffle design. We still search, but we haven’t found anything better.

TFB: Tell me about the transition from pistol suppressors to rifle suppressors.

B&T Rifle Suppressors

Karl Brügger: Yeah, in the beginning, there was much more pistol-caliber demand. We did a lot of, you know, at that time, before 1998, suppressors were free in Switzerland. So between 1991 to 1998, everything we designed and tried out was sold to the civilian market. Mainly the ones who didn’t perform well, we could sell to the civilian market. They were not bad, but development parts and different samples, they always went to the civilian products. We were the only suppressed producer at the time in our country. But we sold a lot to civilians as they were free.

And then the other rifle came up. In the beginning, rifles were not really popular. Thread on, yes, but quick detach was far away from what people wanted or we didn’t see that so we tried certain things. In the beginning, we didn’t weld until we realized without welding, they would fall apart when you really heavily used them. Especially when the first army unit came and we did something in titanium. Oh, God, what a learning experience. Yes. So we realized that’s not going to work and then we start developing and testing.

I think all the big companies and suppressor production today, you know them better than us, are really good. They all have the best engineers and the best CAD systems and the best flow-through thing and they can design and calculate everything. We tried that as well. But in the end, there is one single thing that tells you if it works. That’s the test. In reality. There’s no simulation on the CAD which tells you the result that you would expect. And we learned that the hard way. And I think everybody in the suppressor business will agree with me if they’re honest with themself.

TFB: We see a shift now where some are moving away from decibels and more towards how does it sound to the shooter and whether is it gassy? The health and safety part of it, which we see now with the RBS series. Is that correct to say?

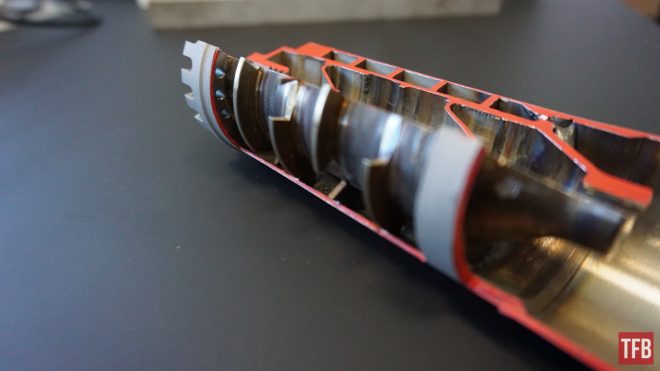

RBS Cutaway

Karl Brügger: Yes, the RBS is clearly the trend at the moment. There is less gas in the shooter’s face and we’re getting similar performance, but there is a bit of a gap to fill. You cannot have no gas in the face, super high reduction, no weight, and no price. That’s just not going to work, especially not for us.

TFB: There’s no free lunch?

Karl Brügger: Yeah, exactly, but we try. We found a bit of a way in the RBS system to get a decent reduction, not too much flash, and less gas in the shooter’s face. Measuring that is rather difficult. So we measure to see how much the rate of fire increases. The good thing about the RBS suppressor is also it’s good for the lifetime of the weapon as the rate of fire is not increasing. So the abuse of the weapon is basically better. So we measure a bit with the rate of fire and we have depends on the weapon. We have between a 1.5% to 5% increase in the rate of fire with RBS. But with Rotex-V we have 20-24%. So it’s a massive difference and you feel it as a shooter.

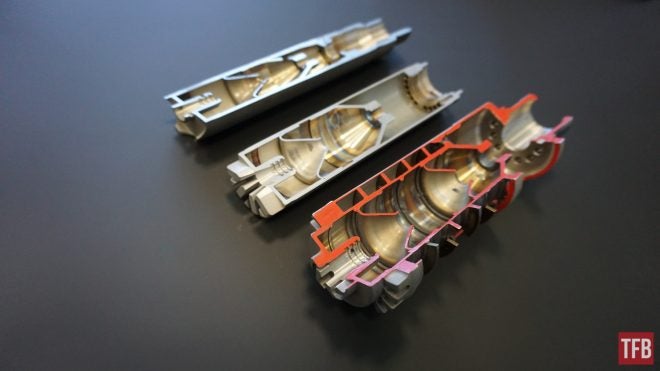

TFB: Here in front of us is the RBS lineup and Rotex series of suppressors. Correct?

B&T RBS, Rotex X, and Rotex V Suppressors

Karl Brügger: Yeah, quite a lot of units in Europe acquire now RBS suppressors for training. But a lot of them, say if we have to go into a theater where our life is in danger, we want the best flash and noise reduction. And we don’t care so much about the gas in our face in the operation as we are engaging targets. So we care less about the gas. We need close to no flash, and good reduction as that is still important. So personally, I see the RBS as a good average suppressor for the general units. But real high-end special operations may go for a standard suppressor. I still think so there is still a gap. What does it help you if you have no gas in the face and you’re healthy, but your first shot produces a slightly higher muscle flash and gives away your position?

TFB: So different suppressors for different applications?

Rotex, Direct Thread, and A2 Mount Suppressors

Karl Brügger: Yes, correct. So that’s all we have as an industry, as people of the industry, we see that, but the customer tells us what he wants and we try to make the best. So that’s why if somebody wants an RBS, but with a 30 DB reduction, then we build it to that level of reduction. If you just want a suppressor which kills a bit of flash, but only should extend four inches, then we build it to be four inches.

TFB: You’ve certainly got a super diverse line of suppressors here. I certainly didn’t know you made a Barrett M82A1 suppressor.

B&T Barrett M82A1 Suppressor

Karl Brügger: Yeah. Fitting directly. We have one that fits directly on the original two-lug muzzle brake.

TFB: Are there a gun or guns that you’re often asked to suppress that are generally difficult to suppress?

B&T M14 Suppressor

Karl Brügger: You know, it depends on how much you have to suppress. We could generally say any caliber from 4.5-millimeter air rifle to 50 BMG, we make a suppressor. Except for shotguns. Shotguns are out. We never went to that. We were quite often asked. And there is the point where B&T, we’re kind of a bit of an idiot in the sense that we only do what we like. And we are not shotgun shooters. We’re not hunters. We do have a hunting line of suppressors as a side project. But we’re not into the shotgun thing, that’s why we don’t do anything for that. That’s why we don’t do a freaking hunting rifle. We’re not hunters and we’re nothing against hunting, but the only thing civilian for the hunting we do really is our screw-on cans, which cost, for in retail, $300 in Europe. You know, we have 22 suppressors. They cost here $80 in the shop for a 42 DB reduction. That’s the only civilian hobbyist side we do for the market, which we are not really at home with. We’re practical shooters.

TFB: Well, I’ll throw you a curveball then. This will be a question that our readers will love, because we’re sitting in a room right now for those readers, with a massive array of firearms. If I tell you in ten minutes, somebody is going to show up. To come and get you, and you have to defend yourself. What are you picking out of this room? What is the gun from B&T that you’re grabbing?

Inside the Conference Room

Karl Brügger: My SIG P365. I would not run for a gun. I would wait for the second I can draw. I carry a 365 in my appendix holster. Okay. I will not run for a gun.

TFB: Is there a favorite B&T product that you’ve released over the years? Personally, the SPR300 PRO is my personal favorite, but do you have a favorite?

B&T MP9 on Display

Karl Brügger: Oh, yeah. It’s hard to say. For us, it’s so much of a hobby. Whatever we take to the range weekly we like. But it’s not necessarily only B&T products. I shot an MP5-10 ten of thousands of rounds in my life as I love it. Everything has its niche or its beauty. Like the SPR, I think I really love the sound and action. Especially the PRO. I shoot KH9, the USW. I still love the TP9. I shot a lot of TP9. Most of the competition I’ve shot is with TP9s as they’re so fast and easy to shoot. Especially on the move. It’s light, it’s fast, and easy to reload. In the worst case, you can conceal it very well. It runs perfectly suppressed. It’s reliable. Shit, you can shoot 6000 rounds without cleaning. Great for me, so I think the TP9 is still a great product.

TFB: Where do you see B&T heading in the future And where do you see the future of the suppressor industry in general?

B&T Suppressor Cases in the Conference Room

Karl Brügger: We still try to grow normally. We listen to the market. We try to do our best in any product range. We do not split between commercial requests or law enforcement requests. We try to combine both of them as we think both markets have the same right to great products. The only thing we clearly don’t do is have two separate lines. We have one quality line. There is no difference if we do something for the US military or law enforcement or for civilians. They are fucking same. We cannot have two lines of production or assembly. No, that’s not going to go to work. We have a saying we never speak about big or small orders. Never. Every order, as long as it gets paid, has the same right of service, quality, and support. That’s the rule of the game.

TFB: What sort of in house testing do you subject your suppressors to?

SILENCER SATURDAY #219: Belt Fed Brutality with the B&T RBS

Karl Brügger: We have this German Army test that’s like 210 rounds in five minutes that we do always. Or the French test, that’s five magazines in a row. You shoot one magazine semi, one in a burst, one more in a burst, the fourth again in a burst, and the fifth in semiautomatic. As fast as you can reload. That’s a general test we do with a suppressor. If it blows up, it blows up. And you know what we do? We buy from every competitor. And mainly we always buy them through a friendly dealer we have. And not all of them that we buy are the best, and some of them fall apart. This testing is just for us. Just good to know. We don’t publish that. We don’t tell anybody which product fails. The only thing we do when it comes to a tender or when we go to customers, we ask them. This is a test the French army did. Just do that with every of your product you buy. Just compare. That’s the only thing. So they’re here for some unknown reasons. Since we’re still 30 years in fucking business. We always joke, I say “How bad do our competitors have to be that we still sell something?”.

TFB: The designs continue to change and it’s like you said, based on the same design. And certainly, pistol cans have remained fairly similar throughout the ages. But I’ve noticed we’re no longer really using monocore cans. Have you noticed any other shifts in the industry since you got started?

B&T Glock Suppressor

Karl Brügger: With the monocore cans in the pistol suppressor market, we tried it as well. We had better results in 45 than we had with the star baffle, but 45 is here not extremely popular on the rifle thing, you know, we had star baffle suppressors the Rotex III is a star baffle suppressor. It’s by far the best in noise and flash reduction, but shit, it’s heavy. And the star baffles, we try to make it in ceramic to make them lighter, but we cannot form that shape of a baffle right now in an economic way. We even tried MIM, but it’s not really good weldable. So we’re kind of stuck. But now with the RBS, the results we get with spacing angling, and creating jets, we’re getting close to the same result. The steps we’re taking going forward, they’re smaller than 15 years ago. Yeah, that’s what we see. And of course, our competitors are getting bigger and better.

TFB: In the last five or so years we saw a shift from a standard pattern 1.5-inch diameter suppressor tube to slightly larger tubes now like those on the RBS. Do you think tubes will get any bigger or stay around this size?

B&T RBS Suppressors

Karl Brügger: No, I hope not. The thing is in that big diameter, take for example the tubing of the RBS. The outer tubing is made out of a thick wall tube, as there is no thin wall tube accurate enough available. So what we do, is we take a three-millimeter thick tube and turn the outside and inside. We machine it to the dimensions we need to be accurate enough to weld and press together. We’re still okay on pricing on suppressors, but there is no Inconel tubing around which we could use in the tolerance we need.

You know, the bigger the tube is getting, the more tolerance the toolmaker needs to get it done. And then we buy 500 meters of tubing. The first one is minus two tenths and the other one is plus two-tenths. But we have a tolerance of plus +/-.050 as needed and that’s why we go a different way. One thing we have to say in our industry we have a lot of good friends, but you’re always alone when it comes to solutions. And we always look for ourselves. We don’t go to speak to another suppressive producer.

The person I really, really, really respect is Phil Dater, former Gemtech. He was here many times and came to measure before, maybe 10 to 15 years ago, when the US was a miss for us. They always had a 35 DB reduction. They were just great numbers that we never achieved. And we said, wow, how the fuck did they do that? And then we invited Phil over and he came with his equipment. Funny, we had similar results to the US. We just measured differently or wrong. So that’s when we realized, oh fuck, there is more to it. We’re not as bad as we thought. So that’s how it came along. And Phil Dater I have a lot of respect for him. We discussed a lot about suppressors.

TFB: In the US, we see this large push towards lightweight silencers. Do you see B&T making a lightweight, maybe not as durable line of suppressors?

B&T Rotex Suppressors

Karl Brügger: We’re pretty hard-headed. We try to stay safe on what we deliver instead of having something blow up. People going into a combat theater I don’t think notice the 50 or 100 grams difference, they usually don’t matter at all, I think. But we like to be on the safe side where our suppressors are not blowing up. I mean, we’ve seen a lot of suppressive blowing up in this 210-round torture test. There are some that just don’t hold up to that. And we think that’s mandatory. And we usually say there must be a reason. We, as a small company, are selected to provide suppressors to some substantial units in Europe or the world. As a provider of suppressors, there must be a reason. So not everything we did, we did wrong. Maybe our bid was the cheapest, but at least we never had blown-up suppressors coming back, which was our fault.

That is our pride. As you know, during the process of production, we use alignment control three times for every single suppressor leaving the house. Every time. And we set that up when we started. We have gauges for everything, and we do that permanently. Every single suppressor. There is not one suppressor from a lot going out without getting gauge.

TFB: It seems like the US demand for SD guns is growing. Do you think that this will continue to be a trend based on the firearms B&T currently selling?

B&T Firearms

Karl Brügger: Haha, you tell me! The thing is, it seems to be a request that people like suppressed guns. Integrally suppressed. And now with the APC, the KH9, the SPC, all of them, we suppress them because we can. We like that shit. We tell everybody when they ask why we did it, it’s because we can. And that’s what I ask sometimes. Why do we need a reason to do something as long as we pay for it?

TFB: I was told recently that the KH9 stood for Karl’s Hobby, is that true?

B&T KH9 Covert

Karl Brügger: Yeah. The base gun is the SITES Spectre. We wanted to buy the tooling, but they were gone, destroyed, and not no longer available. And I have two of them. One doesn’t work anymore after my conversion to Suomi mags due to the coating before it ran bad.

TFB: Will there potentially be a follow-up to the KH or Karl’s Hobby series?

B&T TP9 and KH9

Karl Brügger: So yeah, there is something coming. I don’t know if you should describe them. I can tell you yeah, you can see them, but I’m not going to tell my son. My smallest son, he’s not a gunsmith and he will do engineering for the next two and a half, and half years and I know what I’ll give him. And I have a dream, another dream. I have a project list on my desktop for when I die. My kids know where the file is. When I die those are the things my kids have to go through.

What started off as a semi-formal interview regarding Karl’s history in the suppressor industry ended with his visions for the company moving forward. While this interview certainly does mark where B&T sits currently, I don’t think it’s a full reflection of where the company is headed in the future. B&T has made a point of adapting rapidly to the market, and I certainly wouldn’t be surprised if some attitudes or opinions changed slightly moving forward. I’m certainly excited to see what new products we’ll be seeing from B&T in the coming years.

Thank you to B&T for the invitation and a very special thank you to Karl Brügger for taking the time to share the story behind B&T. I highly recommend watching the video below where James and Karl shoot Karl’s top 5 favorite guns. Thanks for reading.